Composition and Manufacture

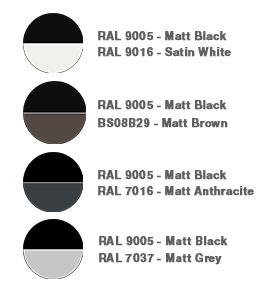

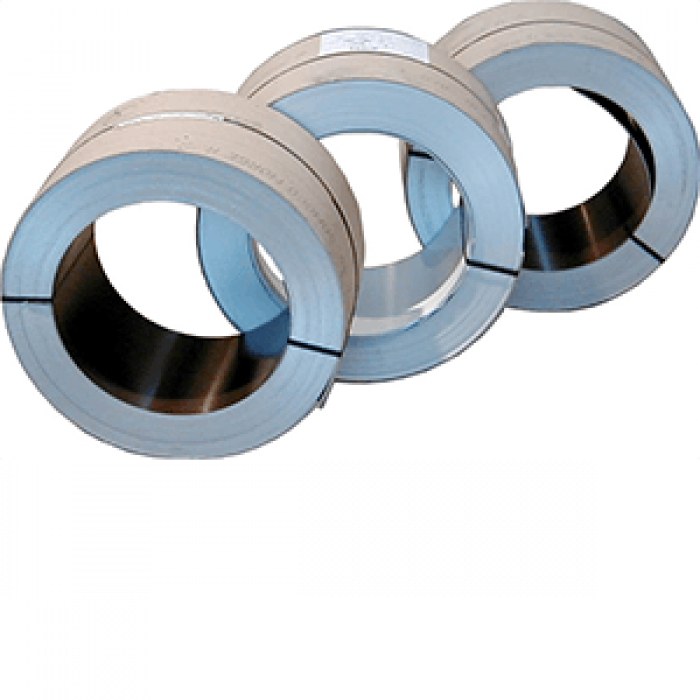

- Gutter formed on site from Hydrocoat Textured 800 Aluminium 0.9mm thick 3105 grade H45 Coil

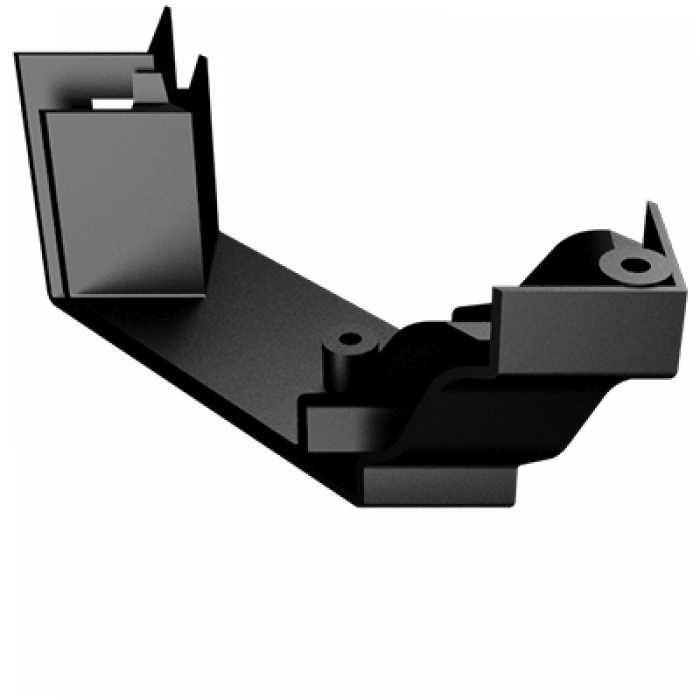

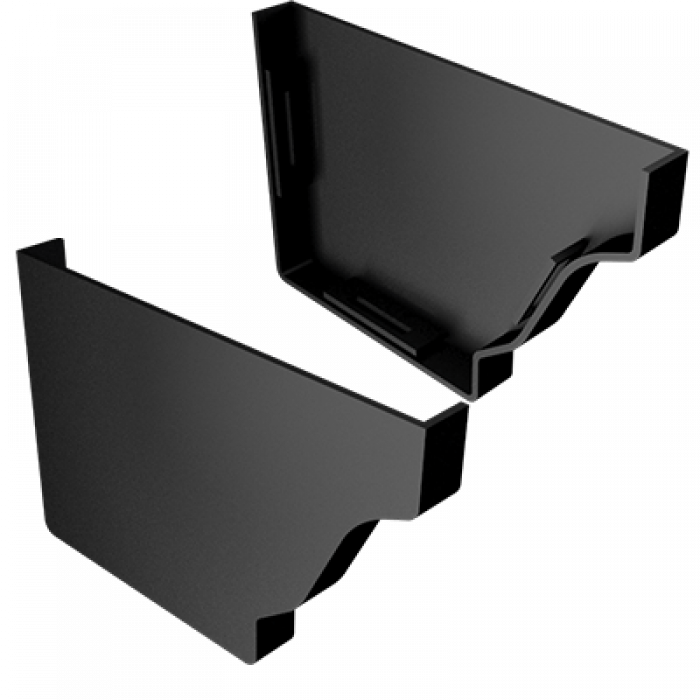

- Components made from colour matched UV stable Polycarbonate

- Matt Finish (40% reflectivity)

- BBA Certificate No 91/2625

- Life expectancy of over 30 years

Seamless Gutter Installation

Downpipes are positioned, and marks corresponding to their centres are made on the fascia board. An exact measurement is taken of the length of the gutter required, noting the marked positions of the downpipes.

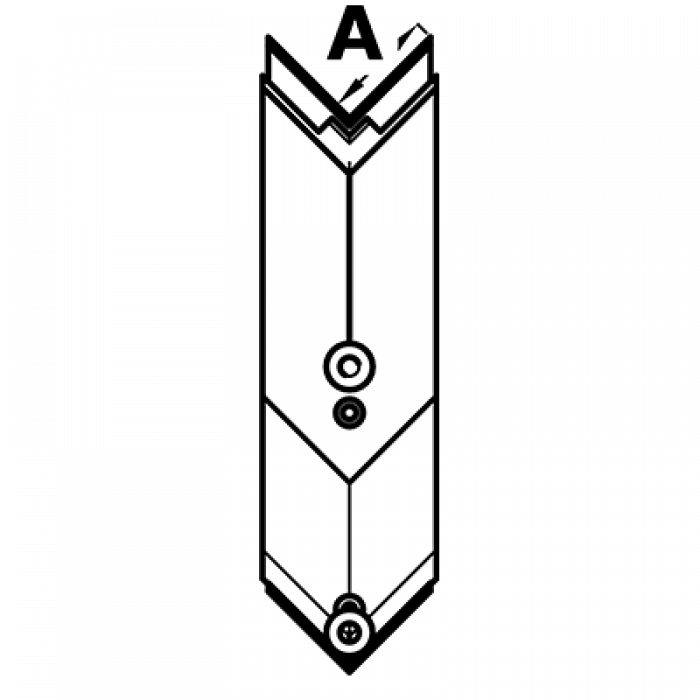

An initial 1m length of the gutter section is roll-formed, and the process stopped for an end cap to be fitted to the open end.

The gutter is crimped centrally near the edge of the rear, front and base to create raised fixing nibs.

The end cap is pressed home activating the internal slotted securing clips to fully engage over the fixing nib, ensuring a non-removable fitting. The completed fitting is sealed inside the gutter with at least three beads of sealant, minimum diameter 7mm.

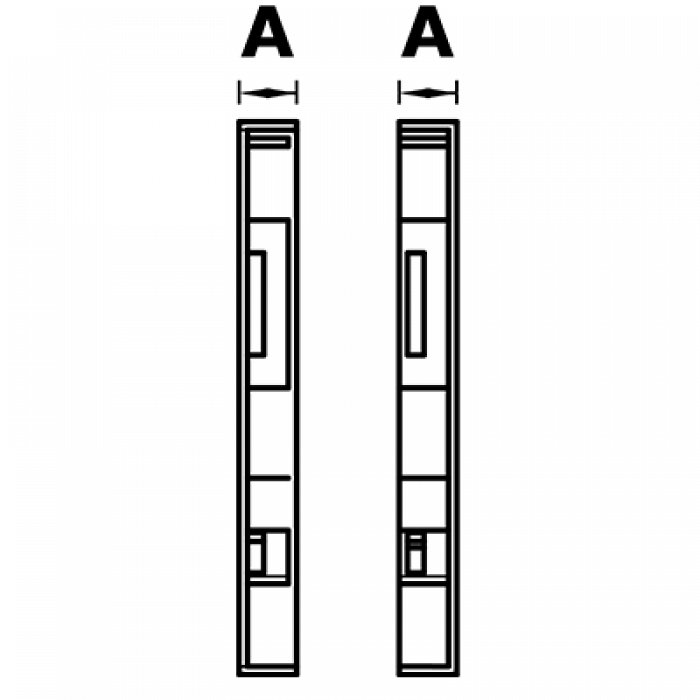

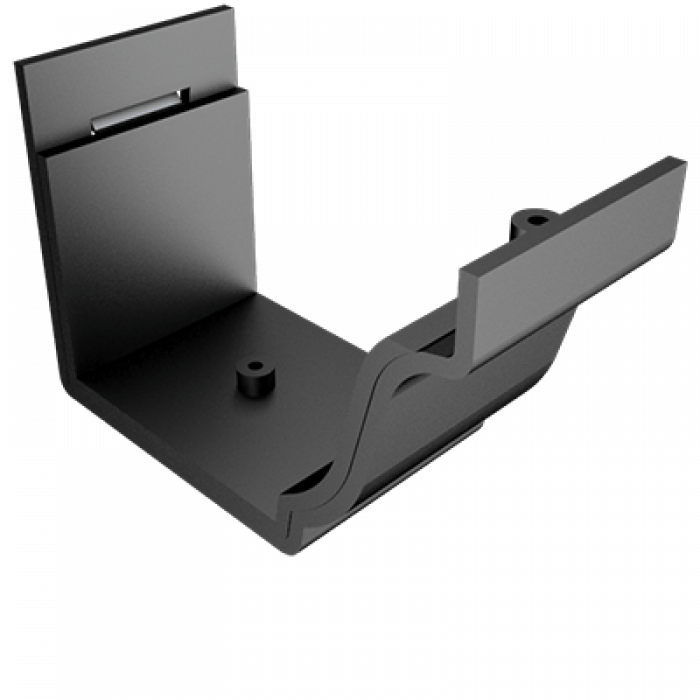

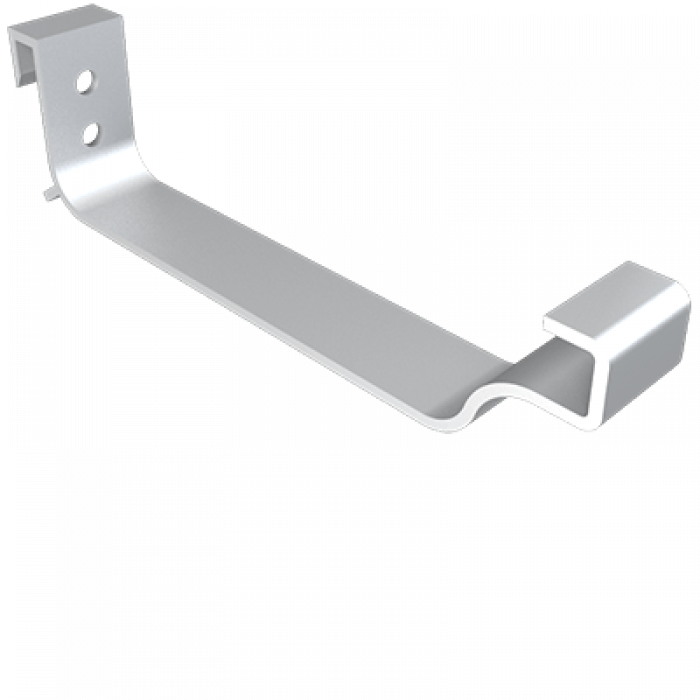

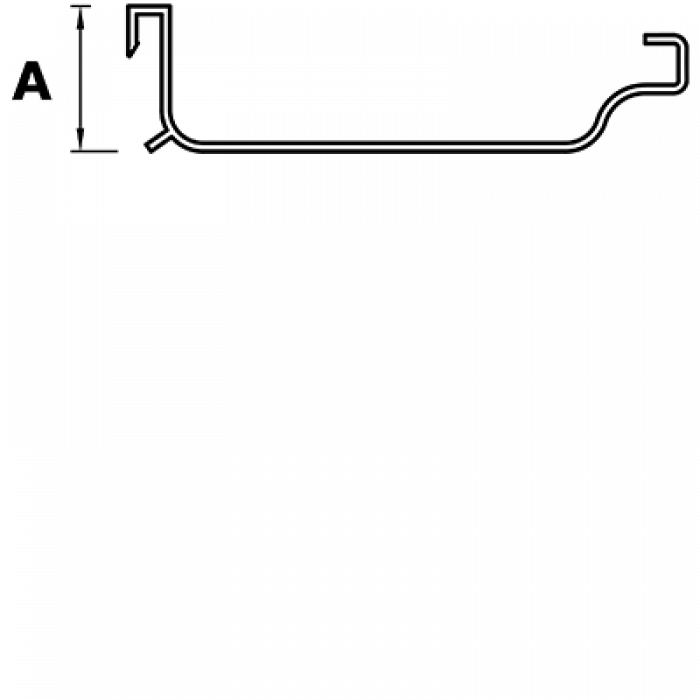

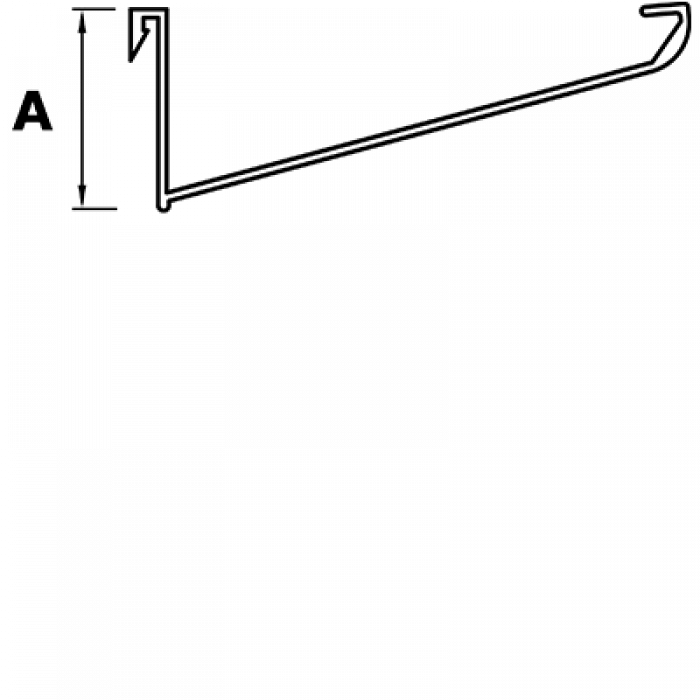

Roll-forming to the exact gutter length is then completed. Aluminium fixing brackets are clipped into position at centres not exceeding 450mm as roll-forming is continued.

The formed gutter is cut to length and a stopend fitted to the remaining open end.

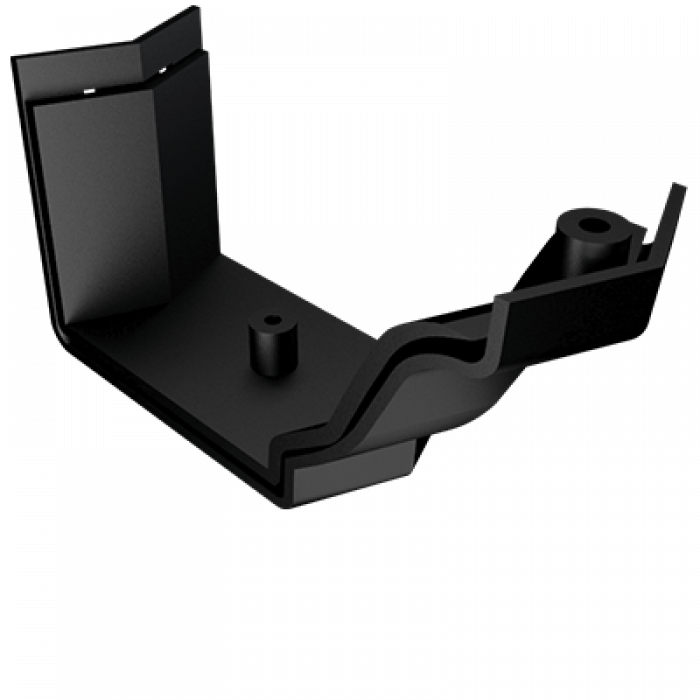

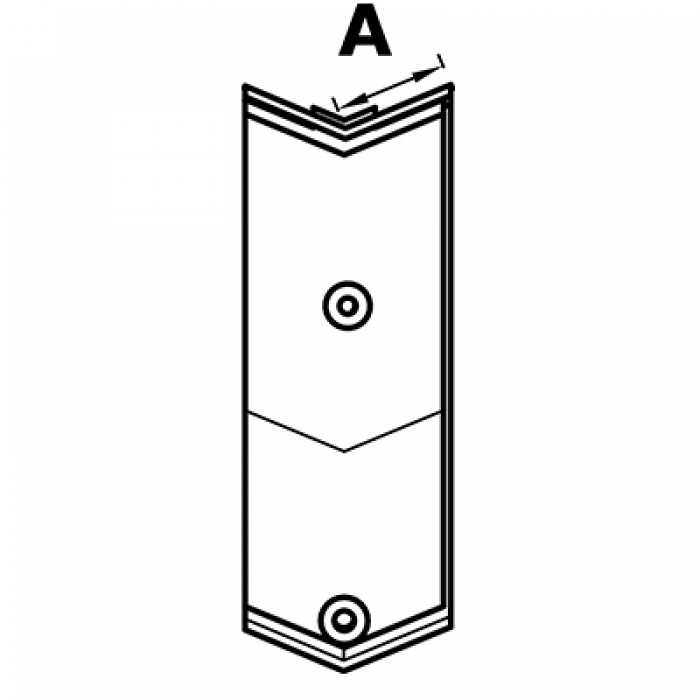

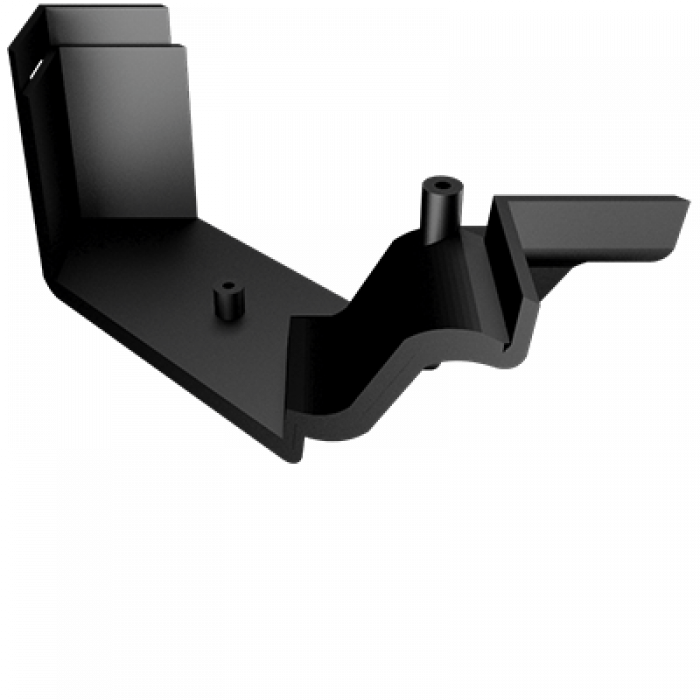

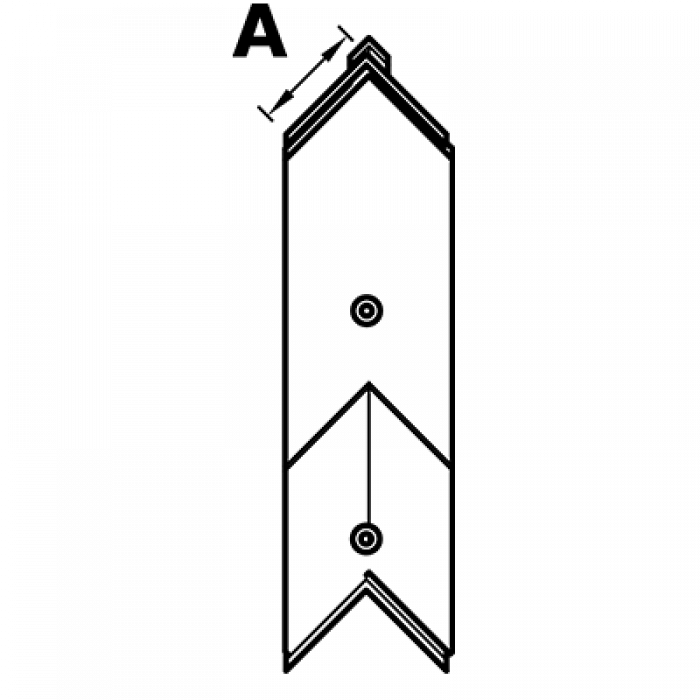

Corners are formed by mitring the ends of the gutter lengths and connecting with a two-piece polycarbonate locking corner fitting, which is then sealed with a specific sealant and secured with stainless steel screws.

Connector expansion joints are installed in the same manner.

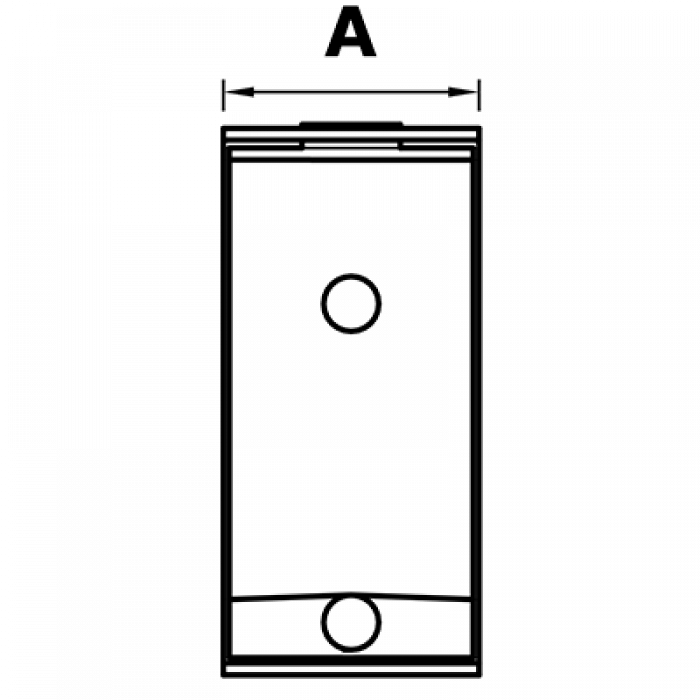

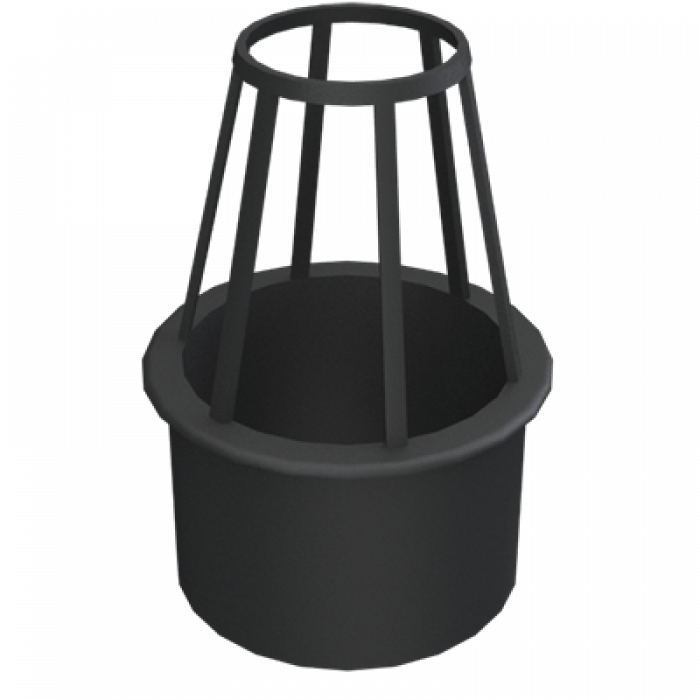

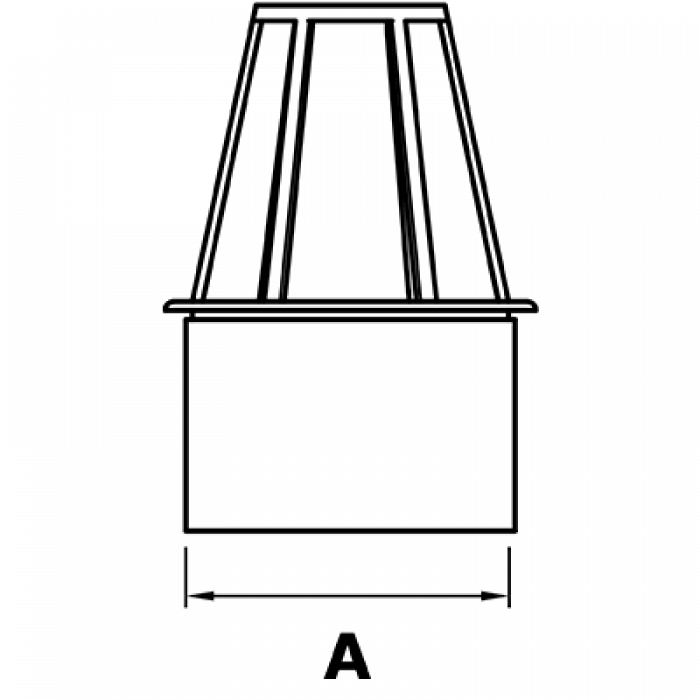

The corners and connectors do not require mechanical fixing and allow for thermal movement. At the downpipe positions in the gutter a hole is formed using a Q-Max cutter into which a low-density polyethylene outlet/leaf trap is fitted and sealed with mastic.

The gutter is positioned and fixed with 4mm diameter, 30mm long stainless steel, self tapping screws.

The fixings are located in pre-drilled holes in the fixing brackets and driven through the back of the gutter into the fascia.