Mustang Ironman seamless gutter machines from ARP, the UK’s sole distributor of the KWM IronMan™ Machines.

ARP can offer a uniquely tailored serviced solution to contractors looking to become involved in the seamless gutter market or start a seamless aluminium gutter business.

Our seamless aluminium gutter machines come with an internationally proven track record and have been manufactured to the highest standards for over 50 years.

Once up and running, you will be invited to take part in the biennial Ironman days event, where your machine will be inspected and adjusted free of charge by the USA manufacturer and ARP-trained staff to ensure that it is running to maximum efficiency, network with other contractors who have made the investment in a machine from ARP and take advantage of special offers and free catering. Click here for more information on the last event.

In between these events, ARP’s team of USA-trained staff can assist with any running issues at our premises in Leicester, your office or site.

If you wish to take training further and gain a certificate to present clients, we also offer the only BBA-certified approved installer program. There is no cost to this training, but this will allow you to promote your business as an installer of the highest quality system available.

Once approved, we can assist with marketing, and our “find an installer” web page is the most popular page on the ARP site directing clients to their local quality installer.

Innovation

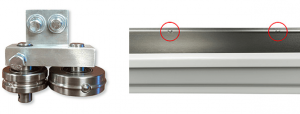

From 2019 all machines supplied by ARP will come with the new Hanger Mark. This clever innovation negates the need for installers to measure each bracket to the correct 450mm centres by adding a dimple to the rear bead at 9” spacings. This will save time on running out material on the ground and working at heights correctly spacing and fixing brackets.

From 2019 all machines supplied by ARP will come with the new Hanger Mark. This clever innovation negates the need for installers to measure each bracket to the correct 450mm centres by adding a dimple to the rear bead at 9” spacings. This will save time on running out material on the ground and working at heights correctly spacing and fixing brackets.

Hanger Mark can also be easily retrofitted to most older Ironman machines. If you are interested, please get in touch with us to check the suitability.

Next Generation Smart Machine

The IronMan Next Generation Smart Machine does the work for you by controlling gutter lengths plus or minus 3mm without manually measuring. With a touch of the screen, the Ironman Next Generation Smart Machine will automatically add for mitres, if applicable, and keep a total of the daily material ran and the total meterage left on a coil. Activate the password protection feature, and you’ll be assured that only authorised personnel can operate the machine.

IronMan™ 5″ Ogee Gutter Machine

| Specifications | |

|---|---|

| Power | 3/4 HP , 110 volt , single phase , 13.6 amp motor |

| Dimensions | L = 250.2cm , H = 122cm , W = 61cm |

| Weight | 499kgs |

| Cradle Weight | 56kgs |

| Drive | Powered polyurethane drive rollers via chain and sprockets |

| Speed | 12 metres per minute |

Features and Benefits

Polyurethane Drive Train

- Eliminates the need to load coil prior to transportation (less material waste)

- Eliminates slippage from cold weather and condensation

.002 Hard Chrome Plated Steel Forming Rollers

- Roll-forms all recommended materials with minimal or no adjustment

- Free-floating forming rollers produce less pressure and allow for more product uniformity

Hanger Mark

- Indentation on the rear of the gutter every 9″ to indicate where to place hangers.

Electrical and Control System

- Push button entry and exit end controls with safety wiring and “jog” feature

- 3/4 HP, 110 volt, single phase motor, 13.6 ampere

Structural Steel Frame

- Welded tubular frame

Modular Turnstile Upright System & Transfer Bars

- Transfer bars (ease of coil loading)