So, the time has arrived to replace the gutters on your home. Where do you start? You could put back plastic gutters as you have already but is this the best you can do?

Seamless gutters are a better solution for your property and here are 10 reasons why.

No.1 – Seamless gutters don’t leak

Seamless gutters are manufactured on-site to the exact measurements of the building in a single length so there are no joints along the length where leaks can occur.

Seamless gutters are manufactured on-site to the exact measurements of the building in a single length so there are no joints along the length where leaks can occur.

Once you have found your approved contractor and arrange a suitable time, they will arrive at site with everything they require to complete the install.

The process starts when the pre-coloured aluminium flat coil is fed through the gutter machine. A series of rollers then manipulate the metal into the gutter shape and continuous lengths, of up to 30m, exits the machine and then are cut to length, ready to be installed. Regardless of how long your house is, most installations will not have any joints along the length.

These lengths are then taken to roof level where they are combined with the leak-free corners and outlets and secured in place to the building.

This whole process is very quick and is certified by the British Board of Agrément to last in excess of 30 years

No.2 – Seamless gutters have low embodied carbon

There is currently a lot of press coverage and public opinion about the environment. The latest UK election, Greta Thunburg and the United Nations Climate Change Conference (COP25) in Madrid (2019) all are saying that we need to change the way we impact the planet. One area that is highlighted and agreed upon is that we need to reduce the amount of embodied carbon created by the way we exist. The targets being suggested is that we become carbon neutral by 2050, but some experts suggest that this is not quick enough.

There is currently a lot of press coverage and public opinion about the environment. The latest UK election, Greta Thunburg and the United Nations Climate Change Conference (COP25) in Madrid (2019) all are saying that we need to change the way we impact the planet. One area that is highlighted and agreed upon is that we need to reduce the amount of embodied carbon created by the way we exist. The targets being suggested is that we become carbon neutral by 2050, but some experts suggest that this is not quick enough.

Aluminium has seen a resurgence in popularity particularly on its suitability for the circular economy and its low embodied carbon. Whilst products made from virgin aluminium are not going to help in reducing embodied carbon responsible sourcing can turn this around. “Environmentally friendly” aluminium must have two main attributes – manufactured from a high percentage of recycled material and manufactured using green energy sources.

Through ARP’s commitment to best material practices and responsible sourcing, our seamless gutter coils are made from a minimum of 78% recycled content and is manufactured using 95% hydroelectricity. By choosing gutters from ARP you are contributing to the reduction in embodied carbon and meeting the targets that scientists are insisting upon.

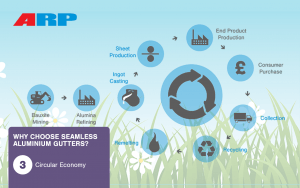

No.3 – Seamless gutters are perfect for the circular economy

The circular economy is a relatively new concept. It often referred to simply as “circularity” and is an economic system aimed at eliminating waste and the continual use of resources. This regenerative approach contrasts with the traditional linear economy, which has a ‘take, make, dispose’ model of production.

The circular economy is a relatively new concept. It often referred to simply as “circularity” and is an economic system aimed at eliminating waste and the continual use of resources. This regenerative approach contrasts with the traditional linear economy, which has a ‘take, make, dispose’ model of production.

Seamless gutters are a perfect example of how a circular economy can work in a closed-loop to help and protect natural resources and lower levels of embodied carbon.

Gutters are manufactured by ARP using low embodied carbon aluminium. The product has a longer maintenance-free life expectancy, as certified by the British Board of Agrément (BBA) than plastic gutters or some other metal systems, thus eliminating the need to revisit the site to perform regular maintenance or prematurely replace.

Once the product does reach the end of its serviceable life (30+ years) the product will have a scrap value, encouraging recycling of the product. This scrap can then be turned into new aluminium products, using 95% less energy than the product made from virgin aluminium and closing the loop from manufacture to use and then re-manufacture to re-use.

This cycle can continue indefinitely, as aluminium does not suffer from a degradation of properties.

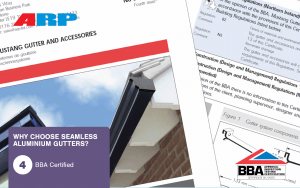

No.4 – Seamless gutters have a certified performance

ARP are immensely proud that our Mustang Seamless Gutters have been certified by the British Board of Agrément (BBA) for nearly 30 years.

ARP are immensely proud that our Mustang Seamless Gutters have been certified by the British Board of Agrément (BBA) for nearly 30 years.

This certification covers all sourcing of materials, storage and distribution of components and the fitting by trained Approved Installers.

In order to maintain this certification, ARP is rigorously audited twice per year and each stage of the process is checked and interrogated to ensure that the quality assurance is maintained.

As the manufacturing of the seamless gutter takes place on-site, out of the back of a van, our Approved Installers volunteer to a minimum of two inspections each year, demonstrating their commitment to ensuring the best quality installations are carried out.

If you would like to find your local installer click here to submit an enquiry form.

No.5 – Seamless gutters are fitted by approved installers

As the actual manufacturing of seamless gutters happens on-site, the British Board of Agrément (BBA) who have certified Mustang gutters for nearly 30 years, insist that our Approved installers are trained to the highest standards and take part in continuous assessment to ensure that the quality of the system is maintained. This ensures that the gutters fitted to your property will be of the highest quality and last as long as the other parts of the roof.

As the actual manufacturing of seamless gutters happens on-site, the British Board of Agrément (BBA) who have certified Mustang gutters for nearly 30 years, insist that our Approved installers are trained to the highest standards and take part in continuous assessment to ensure that the quality of the system is maintained. This ensures that the gutters fitted to your property will be of the highest quality and last as long as the other parts of the roof.

If an installer were to invest in a seamless gutter machine today it would take a minimum of 12 months before passing the acceptable standards to become an Approved Installer.

On the purchase and collection of a machine, all company operatives will receive 3-4 hours of training, that includes the safe operation and maintenance of the machine and most importantly the correct procedures for installing Mustang to the BBA standard.

Over the following 12 months, these new installers will be inspected at least twice before the company will be able to be an Approved Installer and appear on our “Find an installer” webpage.

This twice-annual inspection regime continues for at least 5 years and even then, our longest serving Approved Installers still need to pass an annual inspection.

Make sure that you ask for a copy of the Annual Approved Installer Certificate prior to the company starting work. If you are unsure whether an installer is approved click here to be directed to our “find an installer” page, which displays the current Approved Installers

No.6 – Seamless gutters are economic to install

Seamless gutters are probably the most economical rainwater system available.

Seamless gutters are probably the most economical rainwater system available.

Most people believe that plastic (uPVC) gutters are cheap. This may have been true but increased rainfall and the requirement for gutter sizes to increase means there is now very little difference between the price of correctly sized plastic and seamless aluminium gutters.

To demonstrate this, a survey conducted in 2017, over 130 installers were asked to price given property examples in both aluminium seamless gutters and uPVC options. The average results across the respondents showed that the upfront cost of installing Mustang guttering was within 5%-7% of the cost of installing plastic gutters.

In addition to the initial install costs, plastic gutters are significantly more expensive to maintain and will not last as long as the other elements on the roof, such as tiles, fascias and soffits. The average maintenance requirements for plastic gutters is for the joints to be replaced about every 5-7 years and the system lasting around 15-20 years. If your property is more than a single storey high, then additional scaffolding costs will be required on top of the labour costs to replace the plastic at the end of its functional life.

By comparison, Mustang Seamless gutters are certified by the British Board of Agrément (BBA) to be maintenance free for in excess of 30 years.

No.7 – Seamless gutters are maintenance-free

Unlike any other gutter system, Mustang Seamless gutters do not require ongoing maintenance. This has been tested and certified by the British Board of Agrément (BBA), a certificate that we have proudly held for nearly 30 years. In most cases, the main reason for considering a change of guttering is down to leaky joints.

Unlike any other gutter system, Mustang Seamless gutters do not require ongoing maintenance. This has been tested and certified by the British Board of Agrément (BBA), a certificate that we have proudly held for nearly 30 years. In most cases, the main reason for considering a change of guttering is down to leaky joints.

Seamless gutters are manufactured on-site to the exact measurements of the building in a single length so there are no places along the length where leaks can occur. Outlets (transitions from the gutter to rainwater pipe) are cut into the sole of the gutter and a self-sealing leaf trap/outlet is installed in accordance with the BBA Approved method.

Where corners or ends are required specialist fitting is used to maintain the leak-free system. Corners are formed with the installation of an outer and inner part, interlocking together to form a watertight seal. Again, this is done in accordance with the BBA prescribed method.

All our Approved Installers have been trained and are regularly assessed to ensure that the correct method is being applied, ensuring that the system meets all expectations.

No.8 – Seamless gutters create no additional waste

There has been a lot of publicity and media attention recently focused on the issue of waste. Why? Whilst the environmentally-conscious would like us to use less natural raw materials, less embodied carbon and alternative methods of manufacture, but there is another reason. China.

There has been a lot of publicity and media attention recently focused on the issue of waste. Why? Whilst the environmentally-conscious would like us to use less natural raw materials, less embodied carbon and alternative methods of manufacture, but there is another reason. China.

Up until July 2017, China was the main importer of plastic waste from countries around the world including the USA, Japan, Germany and the UK. Between 2014-16 the UK exported 800,000 tonnes of plastic per year and 500,000 of this was sent to China (HMRC UK trade info website). In July 2017 they decided that they will no longer accept “foreign garbage” as the start of a move to upgrade their industries.

This is the main reason why the issue is being highlighted. The UK Recycling Association have admitted that it lacks the current capacity to process the levels of waste that has been sent to China. UK Environment Secretary Michael Gove has stated that the only way to address the problem is to reduce the amount of plastics used.

The Construction Industry is the 2nd highest consumer of plastics in the UK, behind the Packaging Industry. So, if there is to be a reduction, there needs to be a change to what has been done previously.

Today, when installing plastic gutters, the installer purchases the required number of set 3, 4 or 5 metre sections and components. These are then measured and cut to fit the required final measurements. This will leave several offcuts that will not be used. In addition to this waste, each component is supplied in single-use plastic wrappers, which also needs disposing of.

By comparison, seamless gutters are manufactured on-site to the exact dimensions of the building, i.e. you only make what you need. ZERO WASTE. Each coil can produce up to 137metres and has a recycled cardboard outer and inner coil. All components are supplied in cardboard boxes wrapped in paper protection or for larger quantity items, such as aluminium hangers, woven bags.

No.9 – Seamless gutters are colourfast

We often don’t notice our guttering and downpipes. This functional product is mostly overlooked, with most external renovation thoughts focused around new windows or a new front door. But what about when they start to detract the look of our homes.

We often don’t notice our guttering and downpipes. This functional product is mostly overlooked, with most external renovation thoughts focused around new windows or a new front door. But what about when they start to detract the look of our homes.

If you were to look at your current gutters, chances are they are fairly old and are plastic. When installed they were black but what colour are they now? The easiest way to see the original colour is to look at the unexposed side of the downpipes. Plastic or uPVC gutters are susceptible to fading in UV sunlight. Therefore, after several years, the clips, pipes and gutters are all different shades of what the original colour was.

Seamless aluminium gutters are manufactured on-site from pre-coloured coil. This coil is specifically designed not to fade and resist the rays from the sun. In normal circumstances, the colour will not deviate from the original for 20+ years and after that period only a marginal shade difference will be seen.

No.10 – Seamless gutters don’t expand and contract

One of the biggest issues that affect rainwater gutters is expansion and contraction, i.e. the product increasing or decreasing in length as the temperature changes. If a system is incorrectly installed or doesn’t allow for this movement, it will either buckle, if the product expands, or joints separate if the product shrinks.

One of the biggest issues that affect rainwater gutters is expansion and contraction, i.e. the product increasing or decreasing in length as the temperature changes. If a system is incorrectly installed or doesn’t allow for this movement, it will either buckle, if the product expands, or joints separate if the product shrinks.

If your guttering is leaking then the main reason will be down to the dimensional change that has occurred over time. It is difficult to resolve as, when you repair the leak in the summer, the problem may reoccur in the winter.

Seamless gutters have a very low expansion coefficient or seamless gutters don’t expand and contract as much as any other material. Seamless gutters also are made in a continuous length, so there are no joints that can separate. There is only a requirement to allow for this expansion and contraction if the gutter length is over 30metres. In addition to this, correct installation instructions require the hanger to be placed at 450mm centres and screwed directly through the back edge of the gutter, holding it in place.

Want to find out more about our Seamless Aluminium Gutter Offering, complete the form below.